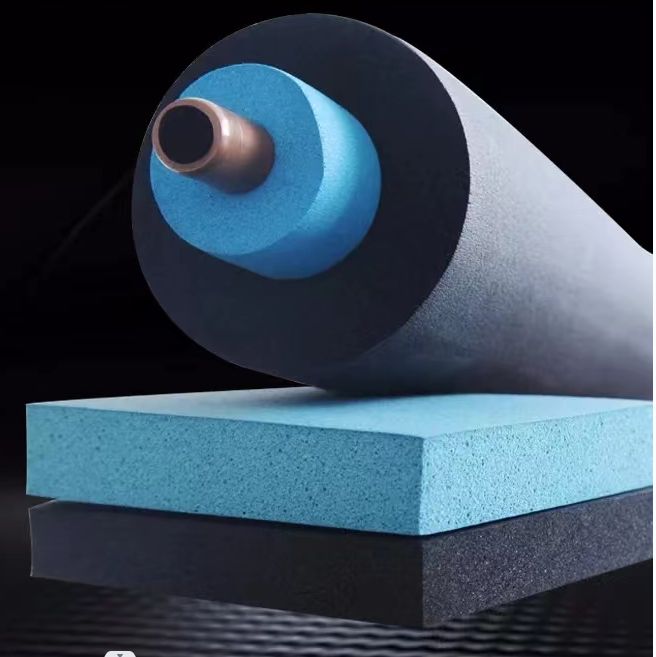

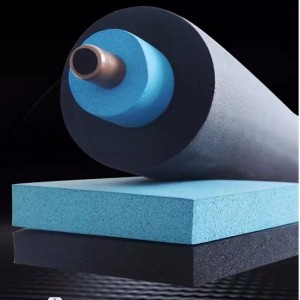

Kriogen quvur liniyasi uchun kauchuk izolyatsiya

Tavsif

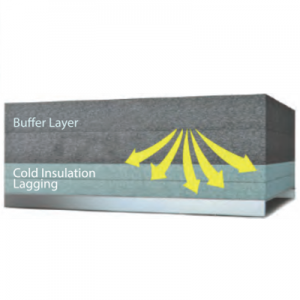

Har qanday qismning zarbasi keng tarqalishi va elastomer materiali tomonidan yumshatilishi mumkin, shu bilan stress konsentratsiyasi tufayli yorilish xavfini oldini oladi. Shuningdek, harorat o'zgarishi stressini kamaytirish sovutish tizimining ko'pikli shisha, poliuretan PIR va PUR kabi an'anaviy materiallardan ustunligidir.

Standart o'lcham

| Kingflex o'lchami | ||||

| Dyuymlar | mm | Hajmi (Uzunligi*Kenligi) | ㎡/Roll | |

| 3/4" | 20 | 10 × 1 | 10 | |

| 1" | 25 | 8 × 1 | 8 | |

Texnik ma'lumotlar varag'i

| Mulk | Base materiali | Standart | |

| Kingflex ULT | Kingflex LT | Sinov usuli | |

| Issiqlik o'tkazuvchanligi | -100°C, 0,028 -165°C, 0,021 | 0°C, 0.033 -50°C, 0,028 | ASTM C177

|

| Zichlik oralig'i | 60-80Kg/m3 | 40-60Kg/m3 | ASTM D1622 |

| Tavsiya etilgan ish harorati | -200°C dan 125°C gacha | -50°C dan 105°C gacha |

|

| Yopiq hududlarning foizi | >95% | >95% | ASTM D2856 |

| Namlik samaradorligi omili | NA | <1.96x10g(mmPa) | ASTM E 96 |

| Namlikka chidamlilik omili μ | NA | >10000 | EN12086 EN13469 |

| Suv bug'ining o'tkazuvchanlik koeffitsienti | NA | 0,0039 g/soat m2 (25 mm qalinlikda) | ASTM E 96 |

| PH | ≥8.0 | ≥8.0 | ASTM C871 |

| Uzatilish kuchi Mpa | -100°C, 0.30 -165°C, 0,25 | 0°C, 0.15 -50°C, 0,218 | ASTM D1623 |

| Siqish kuchi Mpa | -100°C, ≤0.3 | -40°C, ≤0.16 | ASTM D1621 |

Mahsulotning afzalliklari

Kingflex moslashuvchan ULT izolyatsiya tizimi tolali materiallarni kengaytirish va kengaytirish plomba moddalari sifatida ishlatishni talab qilmaydi (bu turdagi qurilish usuli qattiq ko'pikli LNG quvurlarida odatiy holdir).

Bizning kompaniyamiz

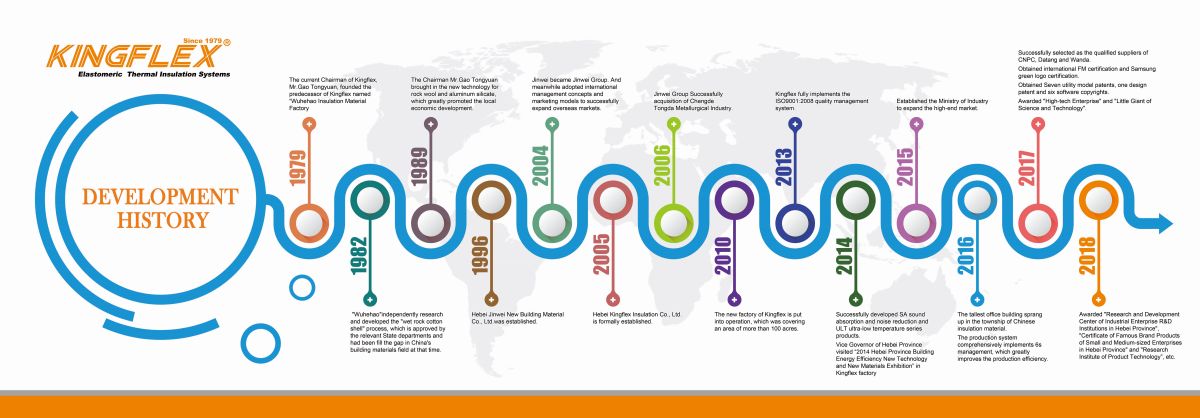

Qirq yil ichida Kingflex Insulation Company Xitoydagi bitta ishlab chiqarish zavodidan 50 dan ortiq mamlakatlarda mahsulot o'rnatadigan global tashkilotga aylandi. Pekindagi Milliy stadiondan tortib, Nyu-York, Singapur va Dubaydagi osmono'par binolargacha, butun dunyo bo'ylab odamlar Kingflexning sifatli mahsulotlaridan bahramand bo'lmoqdalar.

Kompaniya ko'rgazmasi

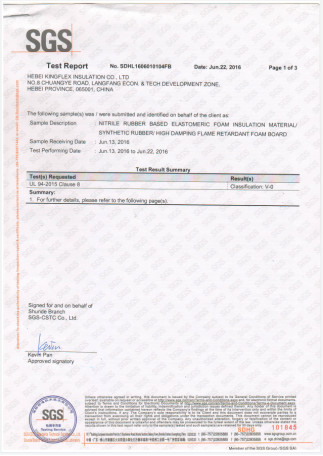

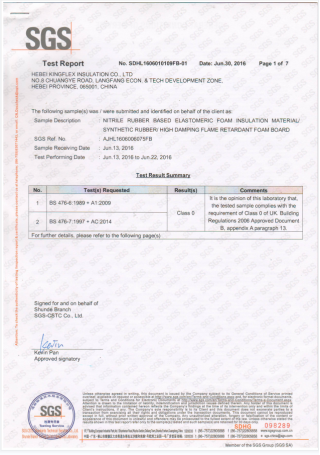

Sertifikatlarimizning bir qismi

Mahsulot toifalari

-

Telefon

-

Elektron pochta

-

Whatsapp